Conventional wastewater treatment flushes valuable resources down the drain — nutrients like nitrogen and phosphorus, essential for fertilizers and agriculture, and minerals like lithium, a key component in EV batteries.

Recovering these resources from wastewater yields significant economic and environmental benefits, yet we’re not doing enough of it. Great Lakes ReNEW is determined to change that.

It’s time to rethink waste and embrace a circular approach. Here’s how three of our research partners are making progress.

Nitrogen, phosphorus, and source-separating toilets

Nearly 25% of the clean water in our building is used to flush human waste from toilets to wastewater treatment plants. Not only is that expensive and wasteful, it also sends nitrogen and phosphorus we’ve consumed in our food back into the environment in a diluted form.

Nancy Love, the Borchardt and Glysson Collegiate Professor and JoAnn Silverstein Distinguished University Professor of Environmental Engineering at the University of Michigan, has a different approach.

She has embraced a new generation of “source separation” technology that recategorizes waste and resources and makes recovery and treatment easier, cheaper, and more energy efficient. She explained that human urine is responsible for the vast majority of nitrogen, phosphorus, and potassium in sewage—all are considered valuable nutrients for fertilizer, but pollutants in wastewater.

As part of the Love Research Group’s work, the Civil and Engineering Department has become a building-scale testbed by installing a urine separation system. It includes a waterless urinal and a source-separating toilet. Urine is separated from solid waste and sent to a processing room with a patented pasteurizer and concentrator. There it is treated, sanitized and converted to fertilizer. Love noted that the department is licensed with the Michigan Department of Agriculture & Rural Development.

As part of ReNEW, Love is working on sensor control schemes, data analysis, and fertilizer product development. Her vision is that source separation systems become part of new construction.

“If we are truly going to have circular, climate-resilient, and climate-responsible approaches to our resources and water treatment, we have to embrace a different approach that doesn’t blend everything together and then treat it as a mixture,” Love explained. “The time to change is now, because the waste systems we invest in and build today will be with us for the next 50 to 70 years.”

Recovering nitrogen from wastewater

Fertilization has enabled agriculture to feed the world, but making it comes at great environmental cost in global energy and greenhouse gas emissions.

It also produces excess fixed nitrogen, or nitrogen gas converted to ammonia, which has devastating environmental consequences, from pollution to biodiversity loss to costly wastewater treatment.

“We use enormous amounts of energy to extract nitrogen from our atmosphere and convert it to a useful form,” said George Wells, associate professor of civil and environmental engineering at Northwestern University and a member of the ReNEW coalition. “This generates enormous amounts of waste nitrogen as a byproduct.”

In collaboration with Keith Tyo of Northwestern and Paige Novak of the University of Minnesota, Wells is focusing on ways to recover nitrogen in our environment by using naturally occurring microbial processes that produce a nitrogen-rich biopolymer. Essentially, this process concentrates dilute nitrogen in wastewater, enabling its recovery. “One of the main challenges to nitrogen circularity is how dilute waste nitrogen is,” Wells explained. “If successful, this process would be a game-changer for nitrogen recovery. ReNEW offers the ability to develop new knowledge and technologies and to work with commercialization partners.”

Wells’ process is currently lab scale, but he’s working on how existing wastewater infrastructure can be adapted to new technologies. “One of the key challenges in the water sector is that our infrastructure is built to last decades, so we need to be able to adapt existing infrastructure to new technologies.”

Revolutionizing lithium recovery

Battery demand for electric vehicles is soaring — and expected to increase 25% annually through 2030. But there is a gap between demand and production: current extraction methods are inefficient, concentrated in a few countries and come at high environmental cost.

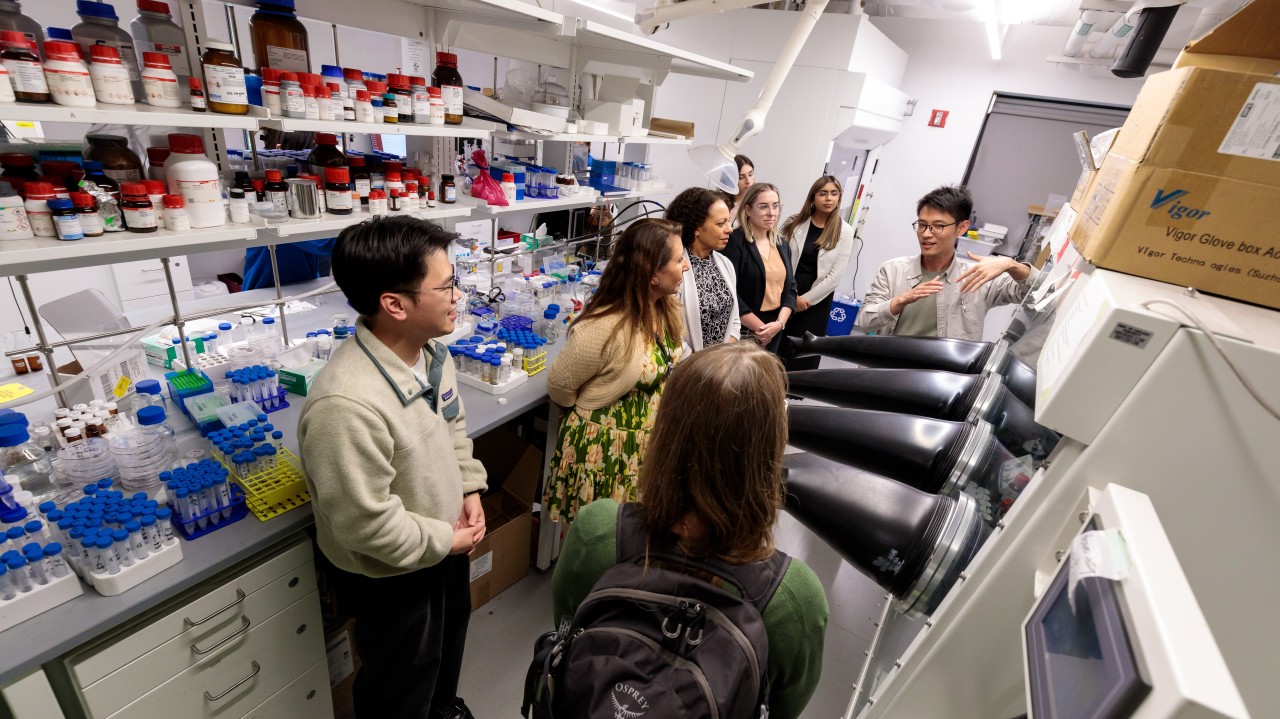

Chong Liu, Neubauer Family Assistant Professor of Molecular Engineering at the Pritzker School of Molecular Engineering at the University of Chicago, has led a breakthrough. The approach isolates lithium based on its electrochemical properties using certain iron phosphate particles, which draw in the mineral like a sponge absorbs water. This method can efficiently pull valuable lithium from seawater, groundwater, and runoff.

Liu explained that her approach will scale up as she and her colleagues refine how the iron phosphate and lithium behave during extraction. “With ReNEW, we can advance our testing, including increasing efficiency, expanding our testing with different water sources, and collaborating with industry partners.”

ReNEW’s focus on resource recovery is raising awareness of the critical need for a circular approach that focuses on separating and recovering nutrients and minerals rather than making or mining more.

“Independently we’re focused on many different targets in treating water,” Liu said. “Together, we can potentially be part of a cohesive, sequential effort to recover as much valuable content as possible.”

A watershed moment for resource recovery

ReNEW’s focus on selective separation and resource recovery has far-reaching economic and environmental benefits. Recovering critical minerals like lithium can reduce our reliance on overseas sources that might hamper electric vehicle production and adoption. Mitigating nitrogen pollution through source separation and recovery can lessen the environmental consequences.

Alaina Harkness, CEO of Current and Great Lakes ReNEW, noted, “ReNEW members are working everyday to turn the promise of resource recovery into reality. When they do, the Great Lakes region will lead the world in water innovation and stewardship. We’re making it happen, one step at a time.”

Note: This material is based upon work supported by the National Science Foundation under Cooperative Agreement No. 2315268