We can’t see, touch, or taste PFAS, but we now know that these forever chemicals are an invisible menace lurking in our drinking water. With new EPA standards set to go into effect, methods to detect, separate, and destroy PFAS are attracting attention.

Selective separation research focuses on sensing and removing specific nutrients, critical minerals and contaminants like PFAS from wastewater. Technologies capable of separating PFAS already exist, including reverse osmosis membranes, activated carbon, ion exchange, electrochemical methods and more. Some of these technologies can even remove or destroy PFAS, but their performance, precision, and longevity can be problematic.

“Even the most mature technologies we have today can fail over time, or prove less effective with short-chain PFAS molecules, which aren’t as easily captured,” said Junhong Chen, co-Principal Investigator of ReNEW, Crown Family Professor of Molecular Engineering at the University of Chicago Pritzker School of Molecular Engineering and Lead Water Strategist at Argonne National Laboratory.

“We need to be able to find and capture specific types of PFAS,” Chen said. “It’s a challenge. When you expose a material to PFAS in water, it will get saturated by other contaminants like heavy metals, nutrients, and antibiotics. These exist at much higher concentrations than PFAS. Sensing is also complicated, because if your sensor is capturing everything in the water, it’s hard to interpret the sensor’s signal.”

Tackling the challenge of selective separation of PFAS

Chen emphasized that ReNEW is focused on pioneering technologies that can selectively sense, separate, and destroy PFAS. To be viable, though, these technologies must be:

- Effective at PFAS removal

- Cost-effective

- Scalable for real-world applications

- Sustainable, ensuring that separation/destruction does not introduce additional contaminants or by-products

“When and where possible, we’re looking at how these technologies can help us with smart water reuse strategy,” Chen explained. “If we’re trying to reclaim reused water for crops, you might want to leave nutrients in but remove heavy metals and PFAS, so that PFAS would not be reabsorbed by crops.”

He pointed out that finding ways to safely, efficiently, and cost-effectively reuse reclaimed water can be beneficial to industry and the environment.

William Dichtel, Robert L. Letsinger Professor of Chemistry at Northwestern University and a member of the ReNEW coalition, concurred on the challenges. His lab has focused on developing new polymers derived from corn that remove trace pollutants including PFAS from water. “One of the challenges that selective separation has to overcome in tackling this problem in the real world is that PFAS contamination is a big deal even at low amounts. And removing PFAS from wastewater is an even bigger challenge because of the presence of other contaminants and compounds.”

“Selective separation of PFAS is one of the grand challenges of the engine,” said Alaina Harkness, executive director of Current and CEO of Great Lakes ReNEW. “As a coalition of 50 partners across six states, we’re focused on what it will take to detect, separate, and destroy PFAS at scale, so we can make it a reality.”

Within ReNEW, researchers have different ideas on how to approach the same goal of selective separation.

“One is to graft molecules onto a low-cost material like activated carbon to achieve selective separation by capturing certain types of PFAS,” Chen said. “Ultimately, though, we must determine whether it’s more advantageous to get to the granular level of a specific PFAS type, or safest to take out all types of PFAS until we truly understand which are most harmful.”

Chen highlighted the work of Brian Chaplin, an associate professor of chemical engineering at the University of Illinois and a member of the ReNEW coalition. Chaplin’s work on electrochemical destruction represents another method for dealing with PFAS. He’s using electricity to drive reactions to break the bonds in the PFAS molecules into smaller compounds that may prove less toxic.

All methods for PFAS detection, separation, and destruction will face a key test: Can they be scaled?

Linda Lee, a distinguished professor at Purdue University with a joint appointment in the College of Agriculture and College of Engineering—also a member of the ReNEW coalition—weighed in.

“Ultimately, technologies have to be scalable for different facilities, countries, states and regions. They have to be effective as well as cost-effective to be feasible for utilities like wastewater treatment facilities.”

The essentials: infrastructure and collaboration

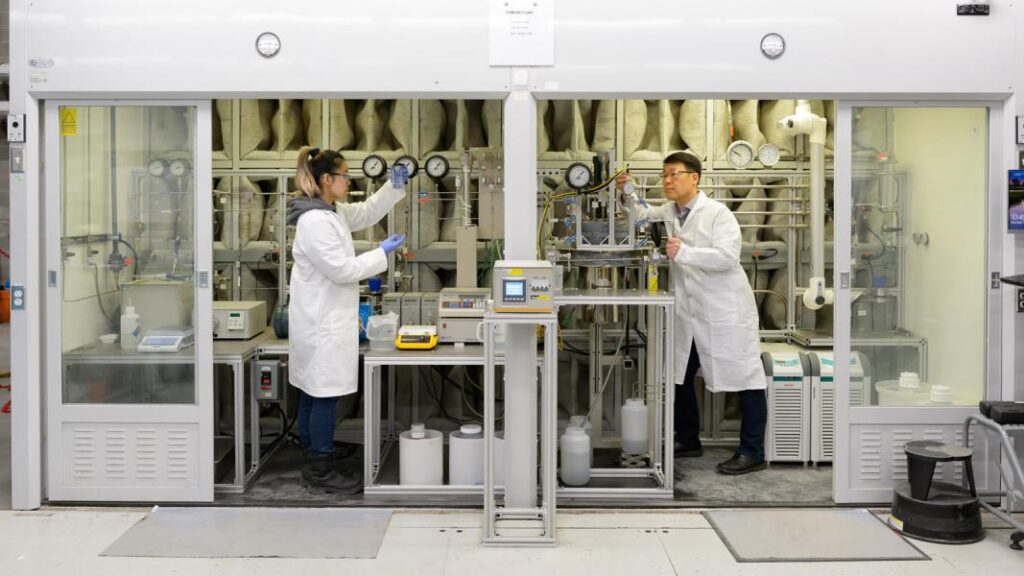

Part of the promise of ReNEW lies in its ability to bring together collaboration and infrastructure across the engine. Argonne National Laboratory’s Materials Engineering Research Facility (MERF) is designed to help scale up manufacturing technologies from lab to market. The facility can be used to validate different materials and technologies.

Dichtel explained, “It’s one thing to find a new material that is promising, but if you can’t make a lot of it economically, you haven’t really solved the societal problem. That’s where our work with MERF is so valuable, because it’s a bridge between what happens in my academic lab and a start-up or larger company that might license the technology. That type of scale up requires a different skill set, and MERF has it.”

“In ReNEW, we’re not working in a vacuum,” Chen concluded. “We’re collaborating with partners like Argonne’s MERF that bring tremendous experience in accelerating the transition from R&D to industry. This helps to keep us grounded. And partners across industry, utilities, and communities can guide us on cost, feasibility and receptivity for different technologies to selectively separate PFAS in drinking water and reclaimed water.”

Interested in getting involved with Great Lakes ReNEW? Contact Us.

Note: This material is based upon work supported by the National Science Foundation under Cooperative Agreement No. 2315268